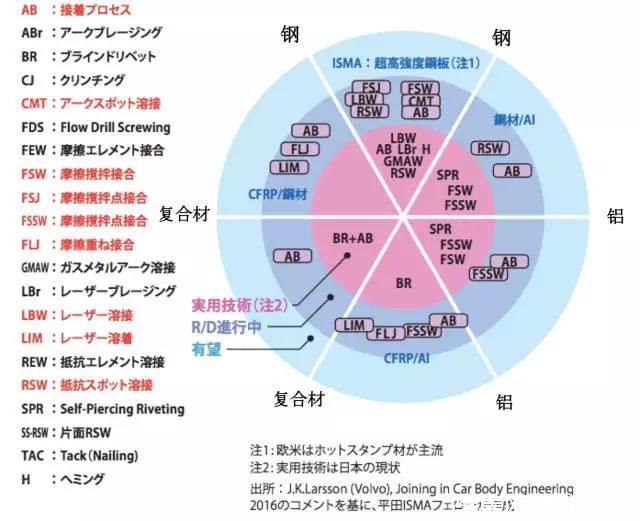

Welding Technique

The above figure mainly illustrates the welding technology and distribution of structural materials use in automobiles. Mainly involving the welding of high-strength steel; aluminum and composite materials; and the welding of dissimilar materials between them. Basically summarized the automobile related welding technology.

According to the technology maturity, it can be divided into three layers:

1) the innermost layer (light yellow): which is the mainstream welding technology use in the industry at present, with Japanese automobile manufacturers as the reference.

2) middle layer (light purple): technology under development.

3) outermost layer (light blue): future trend.

Obviously, heterogeneous material welding is the future development trend, especially metal and carbon fiber material welding.

Something to Notice

1) the welding research and application of high strength steel plate focus on Europe and America;

2) Japan has carried out large-scale application ; And basic technology research of carbon fiber reinforced nylon (CFRP); And metals (especially aluminum and steel). Japan leads the world in carbon materials and welding technology.

3) hydrogen storage vessel welding is not includ in the figure, but companies led by Toyota have invested a lot of energy.

4) high-speed and high-precision flaw detection equipment and technology are not included in the figure;

Automobile parts welding is the most automatic welding technology, which has high requirements for process stability and is also subject to the types of structural materials. Aluminum and carbon fiber are the two most promising materials in the future. So it is of great significance to study their efficient welding.

Automobile parts welding is the most automatic welding technology. Which has high requirements for process stability and is also subject to the types of structural materials. Aluminum and carbon fiber are the two most promising materials in the future. So it is of great significance to study their efficient welding. At present, the quality and stability of high strength aluminum and carbon fiber materials need to strengthen. Some welding technologies and materials are also imported. Automobile main engine plants, scientific research institutions and welding enterprises have not formed an effective industry-university-research association. Which will undoubtedly affect the development and application of technology.

The biggest market for new energy vehicles is China, and it is growing fast. The government is also issuing plans for industrial development. This provides a great opportunity for automotive welding.