Top-Quality welding wire Supplier

Aluminum flux core welding wire

Introduction:

Aluminum flux core welding wire are suitable for aluminum and aluminum soldering, aluminum and stainless steel soldering, aluminum and copper soldering without flux.

| Product Name | Model | Composition | Melting Temperature(℃) | Main Features | Application | |

| Brazing Alloy | Brazing Flux | |||||

| Alum-Alum flux core welding wire

| SMT9008NC | Al-Si12 | KCsAlF4 15%-16% | 577-585 | Good fluidity ; High flux filling quantity, filling evenly Good corrosion resistance; Non-corrosive flux; Material meets ROHS directive; Clean and environmental | Car industry, Household appliance, Electric industry: Radiator; Transform Heat exchanger; Condenser; Evaporator; Aluminum tube, etc. |

|

Copper-Alum flux core welding wire

| SMT9018NC | Zn, Al, other | KcsAlF4 11%-13% | 420-480 | ||

Flux-cored Aluminum Brazing Alloy

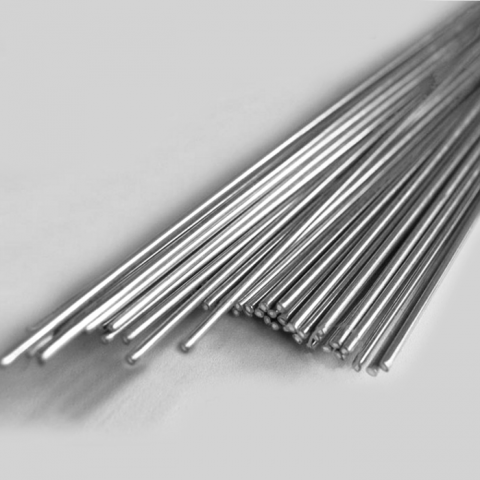

Aluminum to aluminum flux-cored brazing wire

Brazing temperature: 560℃-590℃

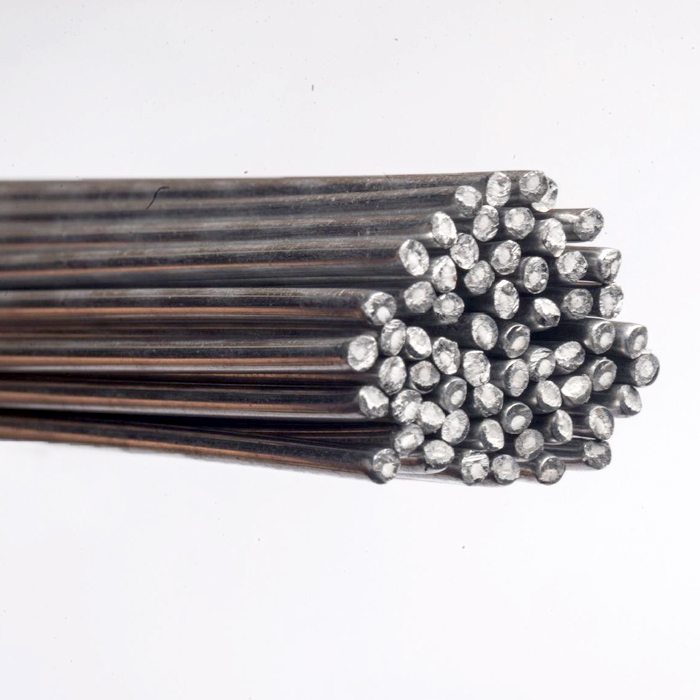

Copper / brass Aluminum flux-cored brazing wire

Brazing temperature: 420℃

Flux-cored brazing ring 焊环

Typical composition of brazing alloy: Aluminum (Al ), copper(Cu ), Zinc(Zn ) alloy

Imported flux: imported from Germany, non-corrosive and non-toxic

| Diameter | 0.5-5.0mm |

| Length

| 350-1000mm |

| Weight (N.W.)

| 0.5kg, 1kg, 2kg |

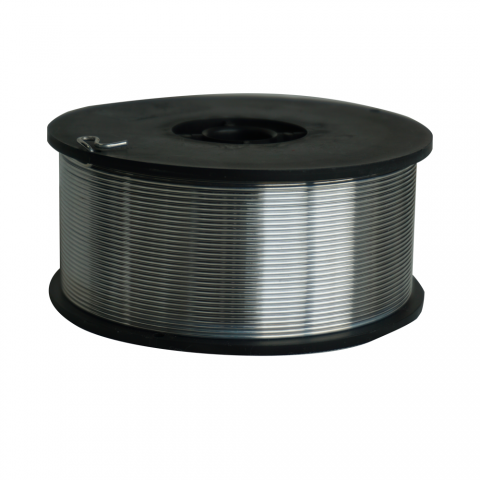

| Form | in various forms such as rod, wire, ring, sheet |

Our Advantages

- Convenient to use, no use of external flux

- Low brazing temperature

- High fluidity

- Excellent crack resistance and tensile strength

- Seamless design to reduce the flux loss

- Very good performance in brazing thin parts

- Suitable for all kinds of flame brazing

- welding effect as good as imported brazing alloy

Typical Application:

- Electrical, cooling system, hardware, the brazing of aluminum to aluminum alloy, the brazing of aluminum to copper / brass