The selection of welding wire diameter depends on the thickness of the welding piece, position of the welding seam, welding level and form of welding joint.

In general, the diameter of the welding wire is selected according to the thickness of the welding part.Thick welding parts, should choose a larger diameter of the welding wire.

When the plate thickness is less than 5mm, we should take the wire diameter = the plate thickness; when the plate thickness is between 5-10mm, the wire diameter is half of the plate thickness.

Welding location:

The basic principle is to carry out flat welding, welding rod diameter can be selected larger;Relatively speaking, vertical welding, horizontal welding and upward welding, welding rod diameter should be selected smaller.In general, the diameter of welding rod is 6mm maximum for flat welding, no more than 5mm for vertical welding, and no more than 4mm for horizontal and upward welding.

Welding level:

In multi-pass welding, in order to prevent the defect of incomplete welding, smaller electrode diameter (usually 3.2-4mm) should be selected for the first layer of welding, and larger electrode diameter can be selected for each layer according to the welding thickness.

Welding joint form:

Lap joint and T joint weld, can choose a larger diameter of the electrode.

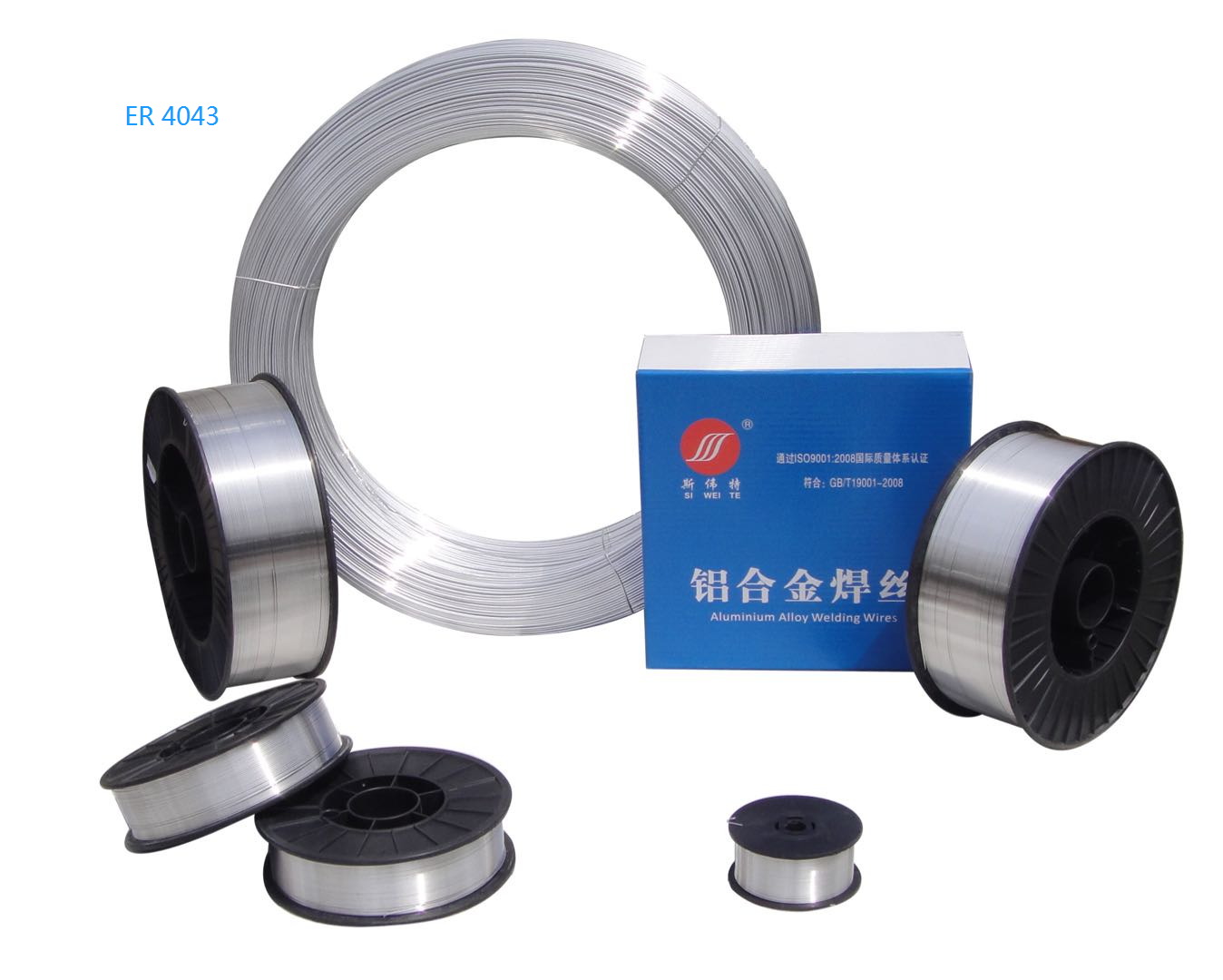

Our products diamter:

MIG:0.8mm, 1.0mm, 1.2mm, 1.6mm, 2.0mm.

TIG: 1.6mm, 2.0mm, 2.4mm, 3.0mm, 3.2mm, 4.0mm, 5.0mm, 6.0mm.

Please feel free to contact me if you have any questions!