What are brazing and its characteristics?

flux cored brazing wire

Brazing, like welding, is one of the oldest ways to join metals together.

What is brazing? What are definitions and characteristics? Many people are still unclear about these, and now let’s tackle those problems in this article.

Definition

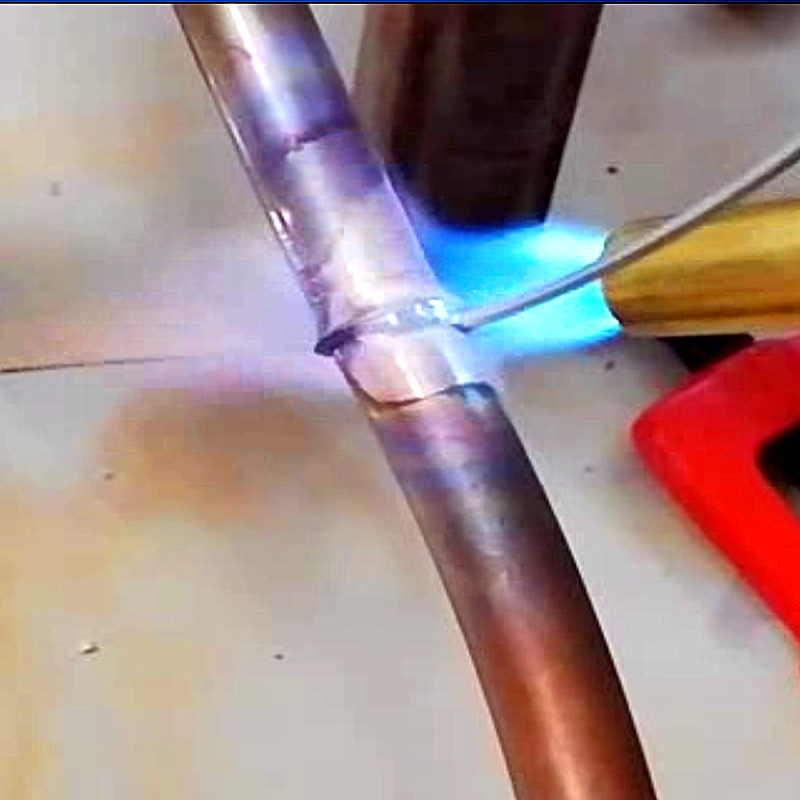

Brazing is a traditional metal joining process in which two or more base metals are joined together by heating and melting a filler metal and filling in a joint. The biggest difference between brazing and welding is if base metals melt or not.

Characteristics

Advantages of brazing

- Brazing filler metal has lower melting point compared to base materials or welded parts. When brazing filler metal melts, base material does not melt. This prevents base metal from melting during welding and reduces deformation.

- The filler metals used in brazing processes are typically self-flux, which means we don’t need to add extra flux. This makes the welding site and weldments much cleaner.

- It is welding technique that allows us to join dissimilar metals together. For instance, we can use brazing to join aluminum and copper. This is especially useful when welding these metals using traditional welding techniques is difficult or impossible.

- There is no strict limitation or requirement on the thickness difference of the workpiece.

- Lower temperature, smooth joints, small changes in microstructure and mechanical properties, small deformation, and accurate workpiece dimensions.

- Some brazing methods can simultaneously weld multiple weldments and have high productivity.

Requires only basic equipment, which makes it quite cost-effective. This means that investment cost for production is relatively low. Compared to other welding techniques that require expensive and complex machinery, brazing is more accessible to join metals together.

Disadvantages

There are a few limitations to brazing that are important to consider.

- Joints strength created through brazing is relatively low compared to other welding techniques. This means we may need to consider alternative methods for heavy-duty applications.

- The joints created through brazing have poor heat resistance, which can limit their use in high-temperature environments.

- Strict cleaning requirements are necessary before it to ensure quality of joints. Any dirt or contaminants on surfaces to be joined can compromise strength and reliability of joints.

If you are in need of brazing aluminum and copper, click here for our brand-new flux-cored brazing wire to help you join them together.