Welding is a critical manufacturing and construction process, and its quality depends on the proper execution of each stage. Among the key stages, backing weld, filling weld, and capping weld play distinct roles, while TIG welding backing and filling directly affect the overall integrity of the weld joint. This article will detail the differences between these three weld stages and explain the essential requirements for TIG welding backing and filling.

1. What Are the Differences Between Backing Weld, Filling Weld, and Capping Weld?

Backing weld, filling weld, and capping weld form a complete welding process, each with unique purposes, operating focuses, and quality standards.

1.1 Backing Weld: The Foundation of Weld Joints

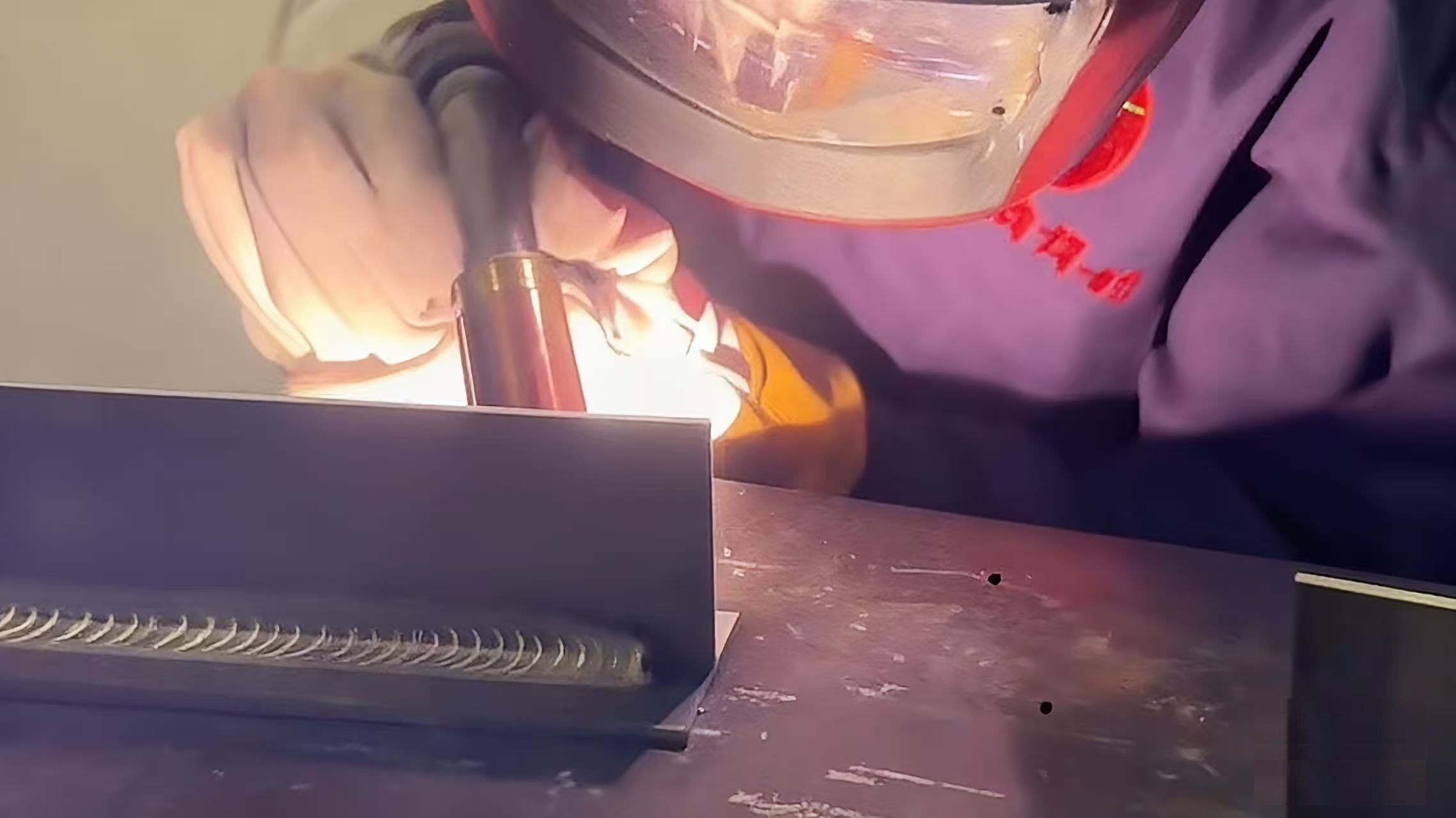

As the first step in welding, backing weld is responsible for forming the root of the weld, laying the groundwork for subsequent filling and capping. Its core goal is to ensure full root fusion between the base metal and the weld metal, eliminating defects such as incomplete fusion and slag inclusion.

During backing weld operation:

- Welding speed is relatively slow to allow sufficient heat input for root penetration.

- Operators need to closely monitor the molten pool to prevent root undercutting or burn-through.

- For materials like stainless steel or high-alloy steel, TIG welding backing is often preferred for its precise heat control and clean weld formation.

1.2 Filling Weld: Build Up Weld Dimensions

Following the backing weld, filling weld focuses on filling the weld groove to reach the required height and width. It acts as a “transition layer” between the backing and capping, ensuring the weld meets structural strength requirements.

Key characteristics of filling weld:

- Welding speed can be moderately increased compared to backing weld, but fusion quality remains a priority.

- Multi-layer welding is commonly used for thick workpieces; each layer must be cleaned to remove slag before the next layer is applied.

- The filling weld does not require strict surface aesthetics but needs to maintain uniform dimensions to facilitate subsequent capping.

1.3 Capping Weld: The Final Finish of Weld Joints

As the last stage, capping weld forms the surface layer of the weld, directly affecting both the appearance and mechanical properties of the joint. It must meet industry standards for surface flatness, smoothness, and defect-free performance.

Critical points for capping weld:

- Welding speed should be balanced—too fast may cause undercutting, while too slow can lead to excessive reinforcement.

- The weld surface must be free from defects like porosity, cracks, or 咬边 (undercut), and its width should extend 1-2mm beyond the groove edges.

- For applications with high corrosion resistance requirements (e.g., chemical pipelines), the capping weld’s surface finish is even more crucial.

2. Essential Requirements for TIG Welding Backing and Filling

TIG welding (Tungsten Inert Gas welding) is widely used for backing and filling due to its high precision and low spatter. To achieve optimal weld quality, the following requirements for TIG welding backing and filling must be met:

2.1 Ensure Full Root Fusion

Root fusion is the most critical indicator of TIG welding backing quality. To achieve this:

- Adjust welding parameters properly: Control welding current (typically 80-150A for carbon steel), arc length (1-3mm), and argon flow rate (8-15 L/min) to ensure sufficient heat penetration.

- Use proper joint preparation: The groove angle, root gap, and root face should comply with welding process specifications (WPS) to allow the arc to reach the root.

- For thick workpieces, consider using a backing strip (e.g., copper or stainless steel) to prevent burn-through while promoting root fusion.

2.2 Maintain Appropriate Weld Shape

A well-shaped TIG backing and filling weld enhances both mechanical performance and corrosion resistance. The ideal weld shape features:

- A slightly convex root surface (for backing weld) to avoid stress concentration.

- Uniform width and height for filling weld layers, with no sudden changes in cross-section.

- No excessive reinforcement (usually ≤3mm) to prevent cracking under load.

2.3 Prevent Common Defects

Defects in TIG welding backing and filling can compromise the weld’s integrity. Common prevention measures include:

- Porosity: Ensure the base metal and filler wire are clean (free from oil, rust, or moisture) and maintain stable argon shielding.

- Slag Inclusion: Use proper wire feeding speed and clean each filling layer before welding the next.

- Cracks: Preheat the workpiece (if required for high-carbon steel) and control the cooling rate after welding.

3. Conclusion

Understanding the differences between backing weld, filling weld, and capping weld and mastering the requirements for TIG welding backing and filling are essential for producing high-quality weld joints. By focusing on root fusion, weld shape control, and defect prevention, operators can ensure welds meet structural, mechanical, and aesthetic standards. Whether in pipeline construction, aerospace manufacturing, or automotive repair, proper execution of these welding stages is key to safe and reliable performance.