Brazing is a widely used joining process in manufacturing, valued for its ability to create strong, precise joints between metals (and even some non-metals). Unlike welding, brazing basics start with a key distinction: it uses a filler metal with a lower melting point than the base material, which melts and bonds to the workpiece without liquefying the base metal itself. This makes it ideal for delicate or complex components where heat damage must be avoided.

1. What Is Brazing? Definition & Key Characteristics

Brazing is defined as a joining method that uses a filler metal (brazing alloy) heated above its melting point (but below the base material’s melting point). The molten filler flows into the joint gap via capillary action, then solidifies to form a strong bond.

Key characteristics of brazing include:

- Only filler metal melts: The base material remains solid, minimizing thermal distortion and preserving workpiece precision.

- Low stress & deformation: Minimal changes to the base material’s structure ensure tight dimensional control.

- Smooth joints: Brazed connections are typically neat and require little post-processing.

- High efficiency: Multiple joints can be brazed simultaneously, boosting production rates.

- Versatility: It can join dissimilar metals (e.g., copper to silver) and even metal-to-non-metal components.

Limitations include lower joint strength and heat resistance compared to welding, as well as increased material consumption for lap joint designs.

2. Common Types of Brazing

Brazing is categorized by heat source, temperature, and filler type:

- By heat source: Flame brazing, induction brazing, furnace brazing, resistance brazing, and laser brazing (suited for high-precision applications).

- By temperature:

- High-temperature brazing (over 800°C)

- Medium-temperature brazing (550–800°C)

- Low-temperature brazing (below 550°C)

- By filler melting point:

- Hard brazing (filler melting point >450°C): Delivers higher joint strength

- Soft brazing (filler melting point <450°C): Used for low-stress applications like electronics.

3. The Brazing Process: Step-by-Step

A standard brazing workflow ensures reliable, high-quality joints:

- Joint design: Select gap size and form (e.g., lap, butt) based on load requirements.

- Prep work: Clean the workpiece surface to remove grease, oxide films, or contaminants (critical for aluminum brazing).

- Assembly & positioning: Secure components with fixtures, spot welding, or rivets.

- Apply filler metal: Place the brazing alloy (e.g., wire, paste) near the joint.

- Select flux: Choose a flux to dissolve oxides and prevent re-oxidation (essential for aluminum brazing).

- Set parameters: Control heating temperature and duration to avoid overheating.

- Heat & braze: Melt the filler metal to enable capillary flow.

- Post-braze cleaning: Remove flux residues with mechanical or chemical methods.

- Quality inspection: Verify joint integrity (e.g., via visual checks or pressure testing).

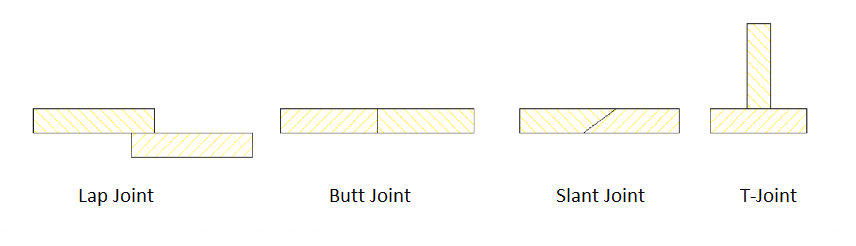

4. Brazing Joint Forms: Which to Choose?

The most common joint forms include:

- Lap joint: Highest strength (preferred for load-bearing parts); typical overlap length = 3× base material thickness (max 15mm for optimal capillary flow).

- Butt joint: Lowest strength; used for non-load-bearing components.

- Slant joint: Moderate strength; balances load capacity and assembly ease.

- T-joint: Used for perpendicular connections (e.g., structural frames).

5. Aluminum Brazing: Optimize Performance with Our Products

Aluminum brazing poses unique challenges (e.g., persistent oxide films, high thermal conductivity) — but our specialized materials address these issues:

- ER4047 Aluminum Filler Wire: A eutectic aluminum-silicon alloy (12% Si) with a low melting point (532–571°C) and excellent fluidity. It minimizes hot cracking and improves joint shear strength, making it ideal for aluminum radiators, automotive parts, and alloy assemblies.

- Aluminum Brazing Flux (FWB201S): A high-activity flux with a melting point of 420°C, designed to dissolve aluminum oxide films and promote filler wetting. It works seamlessly with ER4047 wire in 450–620°C brazing processes (flame or furnace).

Our ER4047 filler wire and FWB201S flux are engineered to enhance aluminum brazing reliability, reduce rework, and deliver consistent, high-quality joints for industrial applications.

Brazing is a versatile, precise joining process critical to industries like aerospace, automotive, and electronics. By understanding brazing basics (definition, types, processes, and joint forms), manufacturers can select the right methods and materials for their needs. For aluminum brazing applications, our ER4047 filler wire and specialized flux provide tailored solutions to overcome material-specific challenges.