Welding

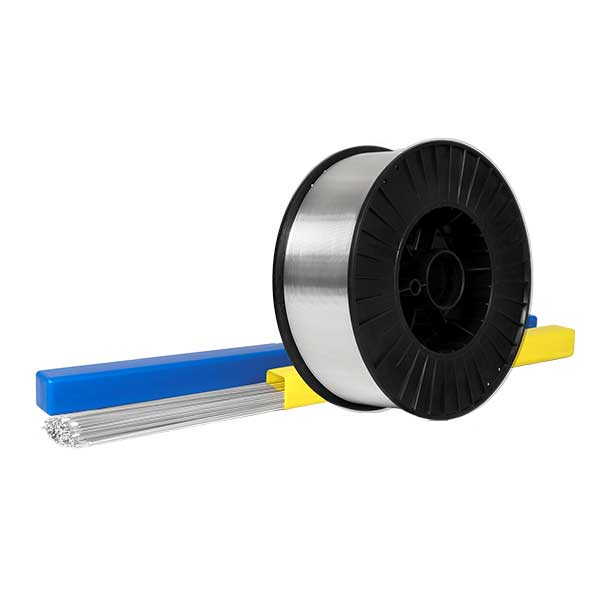

We Specializing in welding materials, we offer high-quality rods, wires, and equipment for industrial and repair needs. Durable, efficient, and trusted.

- Al-Al flux cored brazing wire >

- Cu-Al flux cored brazing wire >

- Brazing Rings >

- Aluminum brazing flux powder >

- Silver brazing flux powder >

ER5087 is a zirconium-modified Al-Mg welding wire/rod for Mg ≤5% alloys. Ideal for high-strength, corrosion-resistant Al-Mg structures, especially super duralumin and Al-Si alloys.

ER4043 (Al-Si5) is one of the oldest and most widely used welding and brazing alloys. SIWEITE ER4043 can be classified as a general purpose type filler alloy.

The ER5356 is the most commonly used MIG filler wire. It welds 5000 series and 6000 series aluminum alloy .

ER5183 is a special aluminium alloy solid MIG wire containing about 5% Magnesium and about 0.7% Manganese for improved weld strength and resistance to sea water.

ER4047 is the eutectic aluminum silicon alloy welding wire with about 12% Si element. Suitable for Al-Si, Al-Si-Mg, Al Si mg Cu wrought aluminium and aluminium (7%Si) argon arc welding.

ER1100 (commonly referred to as Al99.5) is a 99% aluminum filler metal that is available in spools or cut

lengths for MIG or TIG welding processes.

ER1070 is a kind of pure aluminium welding wire with the aluminium more than 99.7%.

1080A is 99.80% aluminium filler typically used on similar base metal such as 1060, 1070, 1080, 1100,1350 and 3003.

ER5554 is a magnesium-manganese aluminum alloy filler metal specifically engineered for welding 5454 and similar base metals like 5154, 5254, and 5456. Compared to ER5356, it contains more manganese and zinc, providing superior ductility and enhanced crack resistance. Ideal for chemical tank welding, it offers high-temperature service up to 65°C.

ER2319 is an aluminum welding wire with an elevated copper content (6%)and a controlled manganese. It is heat treatable and produces higher strength and ductility than the 4xxx series filler alloys when welds in 2014, 2036, 2219 and Al-Cu casting alloys are post welds heat-treated.

SWT Drum Wire is new-type aluminum welding wire developed by our company for robotic welding, fully automatic and semi-automatic welding applications. The drum wire is available in 50kgs and 80kgs packages, equivalent to over 7 and 11 standard spool wires respectively. The large-diameter drum ensures the wire comes out straight and twist-free, significantly improving productivity and saving wire consumption.