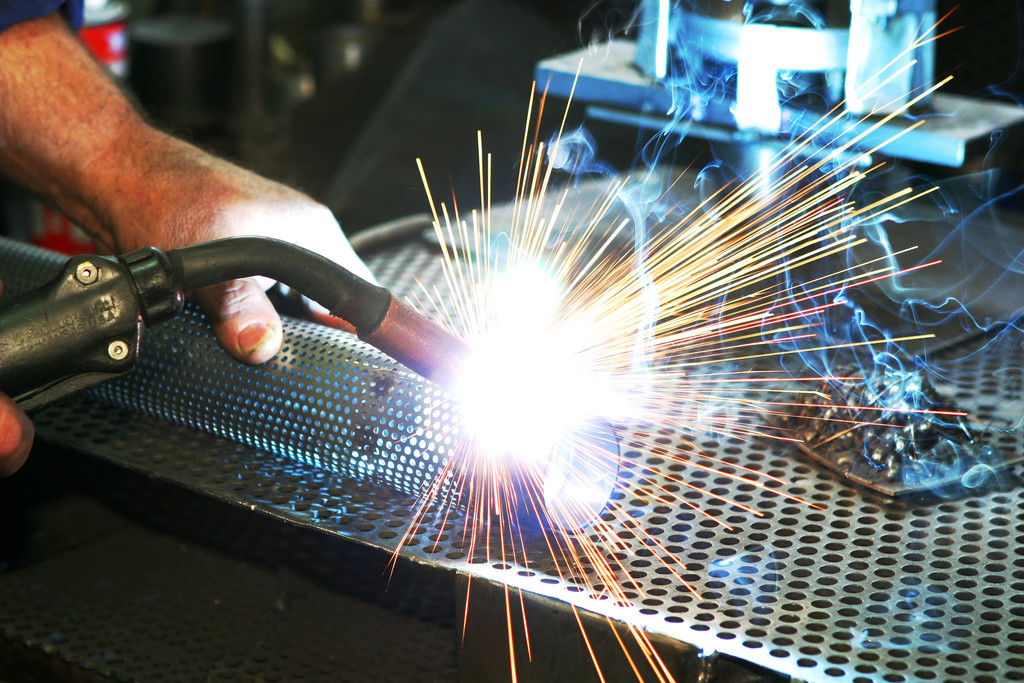

How to find the right current quickly when welding with aluminum wire

Theoretical formula for current regulation

How is the current of the welder adjusted? Generally according to the empirical formula I = (35-55) d. Where I is the welding current (A) and d is the diameter of the electrode (mm), calculate a rough welding current, and then perform a test welding adjustment on the steel plate until the appropriate current is determined.

How to determine the size of the welding current

Listen to the sound

When the welding current is large, the sound of beep is like the water of a large river; +when the welding current is small, the sound of “sand” is emitted, and the crisp squeak is mixed.

Observe the splash condition of the aluminum welding wire

When the welding current is too large, the arc blowing force is large, and the molten metal with larger particles splashes outside the molten pool, and the cracking sound is large when welding, the surface of the weldment is not clean; the welding current is too small, the welding rod is melted slowly, and the arc blowing force is small. The slag and the melt are difficult to separate.

Observe the melting condition of the aluminum welding wire

When the welding current is too large, after the welding rod continuously melts away most of the roots, it can be found that the remaining part is reddened; when the welding current is too small, the arc burning is unstable and the welding rod is easy to stick to the weldment.

Look at the shape of the molten pool

When the welding current is large, the elliptical molten pool has a long axis; when the welding current is small, the molten pool is flat; when the welding current is moderate, the molten pool is shaped like a duck egg.

Check weld formation status

When the welding current is too large, the weld number of the weld metal is low. The penetration depth is large, and the undercut is easy to occur. When the welding current is too small, the weld number of the weld is narrow and high, and the joint between the two sides is poor. When the welding current is moderate, The weld number of the weld metal is moderate, and the weld metal on both sides of the weld is well bonded to the base metal.

———————————-

Sweite welding consumables are mainly aluminum and aluminum alloy welding wire: 1100/1070/5356/5183/4043/4047, shape: straight bar/wire wire/circle wire, specification: 0.9mm–5.0mm, contact number: 13938502789, Welcome calls to discuss cooperation!

read more Aluminum Welding Cheats – Optimization Method for Aluminum Alloy Welding Deformation

Comment *