Home » 3D printing » ZL 114A (ZAL Si7Mg1A)

The SWT ZL114A aluminum alloy welding wire is custom – designed for 3D printing of 114A aluminum alloy. Silicon, a vital alloying element in aluminum alloys, significantly impacts the mechanical properties, thermal stability, and corrosion resistance of aluminum alloys. The precise proportion of silicon not only ensures stability during the welding process but also makes the weld structure denser and greatly improves crack resistance.

The SWT ZL114A aluminum alloy welding wire is custom – designed for 3D printing of 114A aluminum alloy. Silicon, a vital alloying element in aluminum alloys, significantly impacts the mechanical properties, thermal stability, and corrosion resistance of aluminum alloys. The precise proportion of silicon not only ensures stability during the welding process but also makes the weld structure denser and greatly improves crack resistance.

The SWT ZL114A aluminum alloy welding wire is custom – designed for 3D printing of 114A aluminum alloy. Silicon, a vital alloying element in aluminum alloys, significantly impacts the mechanical properties, thermal stability, and corrosion resistance of aluminum alloys. The precise proportion of silicon not only ensures stability during the welding process but also makes the weld structure denser and greatly improves crack resistance.

WIRE COMPOSITION (%)

| Si | Cu | Mg | Zn | Mn | Ti | Be | Al | |

| Requirements-ZL 114A | 6.5-7.5 | – | 0.45-0.75 | 0.10-0.20 | 0-0.07 | Bal. | ||

| Typical Results | Bal. |

Conforms to: GB/T1173-2013

Key Features

Application

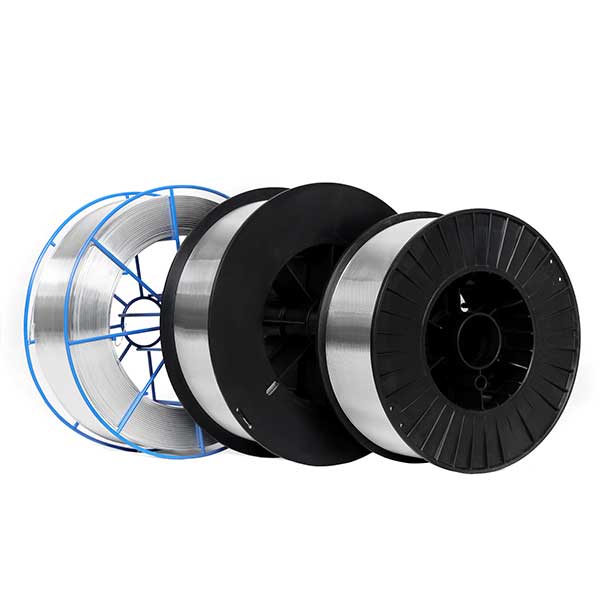

Diameters/Packing

| Type | Spool Diameter | N.W. per spool | Wire Diameter |

| MIG wire | D300mm D270mm | 6kg-7kg | 0.9mm 1.0mm 1.2mm 1.6mm |

| D200mm D100mm | 2kg 0.5kg | 0.9mm 1.0mm 1.2mm | |

| TIG wire | Length: 1000mm | 5kg 10kg 20kg | 1.6mm 2.0mm 2.4mm 3.0mm 3.2mm 4.0mm 5.0mm 6.0mm |

Need a reliable welding wire solution? Fill out the form below, and we’ll send you a personalized quote within 24 hours. Let’s get started!