How to avoid weld porosity when welding aluminum welding wire to work-piece

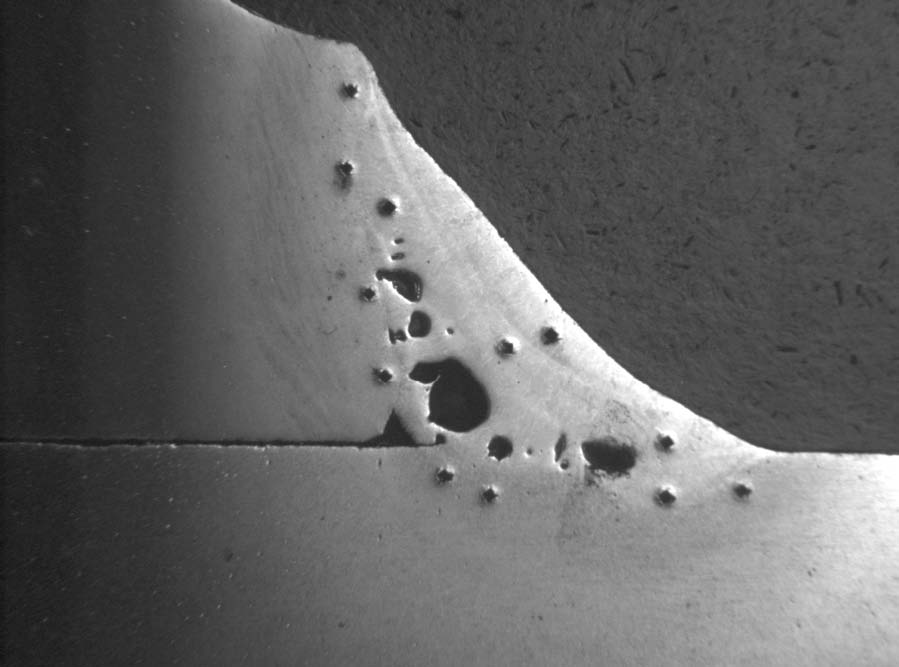

When you weld aluminum welding wire to work-piece, it always appear weld porosity. Especially for a new welder, weld porosity is a difficult problem to solve. The quality of aluminum welding wire has big effect to weld porosity. Meanwhile, if the pre-treatment of the base metal is not well, porosity will appear.

The top quality manufacturer of aluminum welding wire from China-Gongyi Siweite Welding Material Co., Ltd. We have been focus on producing aluminum and aluminum welding wire since 2003.

In the last 16 years, we continue to innovate. Now we are using the world’s advanced continuous casting and direct rolling process. The aluminum welding wire produced in this way has good quality, high density and less hydrogen ions. And it can reduce the porosity of aluminum welding wire inside from the start of the production process.

Besides, there’re some external cause of weld porosity need to attention.

Reason 1 of porosity while welding aluminum welding wire

You aren’t keeping the MIG gun at the correct angle when weld .

You should try to maintain about a 15 degree angle with your MIG gun. Laying the gun over too far will cause you to lose gas coverage, and can even bring in more atmospheric gases. When using the GMAW, FCAW, or SMAW processes remember to angle the gun and the electrode at around 15 degrees.

Reason 2 of porosity while welding aluminum welding wire

You’re out of gas.

This might seem like an obvious mistake, but when you’re in the middle of a project and time slips by you, you’ll forget to check your tank levels. Once you run out of gas, then you have no gas coverage whatsoever, and your welds will have pinholes and wormholes all throughout. At this point, you have no option but to grind out those welds and lay new ones.

Reason 3 of porosity while welding aluminum welding wire

Your MIG hose is pinched.

Whether your feeding a new spool of wire through your machine, or your laying a weld, having any sort of impedance will keep the wire (or gas) from making it to the gun. Make sure your line isn’t being pinched, and if you’re adding new wire then try to keep the hose as straight as possible to avoid any hangups.

Reasion 4 of porosity while welding aluminum welding wire

You didn’t properly clean your metal.

If your metal is oily, greasy, and even rusty it will release gasses that reduce the weld penetration you get in the metal when welding. It’s recommend that you hit your workpiece with a grinding wheel or wire wheel.