Test Method

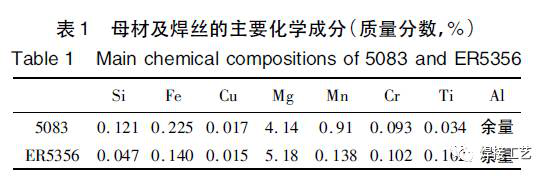

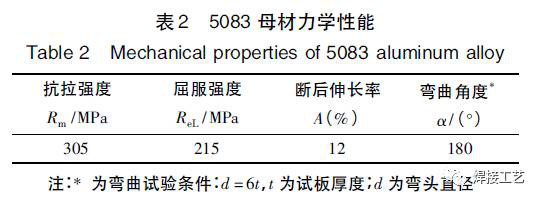

The welding test base material is 5083 aluminum alloy plate. And the size of the test plate is 350 mm × 175 mm × 12 mm. Filler wire selection ER5356, diameter is 1.0 mm and 6.0 mm two. Where the wire use for backing welding, and 6.0 mm wire for filling. In addition, the method of melting electrode argon arc welding (MIG welding) use for base welding . And tungsten electrode argon arc welding (TIG welding) use for filling. The composition of base metal and welding wire showing in table 1

Among them, the test use ER5356 aluminum alloy welding wire produced by Gongyi Siweite Welding Material Co., Ltd. Which adopt the horizontal continuous casting and continuous drawing method. With high yield and low equipment investment. Noting that the melting temperature should be controlled at 700 ~ 750 ℃. Because the temperature too high or too low melting temperature will reduce the processing performance of the wire.

Manufacturing Procedure

The following procedure is: return fire → peeling → drawing → degreasing → layering → inspection → packaging. With the foreign high quality wire production process. In annealing and drawing process to add a stripping. Not only to ensure the quality of the wire surface. But also to reduce the weld hole. In addition, in the welding wire smelting process added quality fraction is 0.000 2% ~ 0. It was found that during smelting. A layer of beryllium oxide film found in the melt to improve the oxidation resistance. Reduce the burning loss of Mg elements. And reduce the number of broken wires in the drawing process.

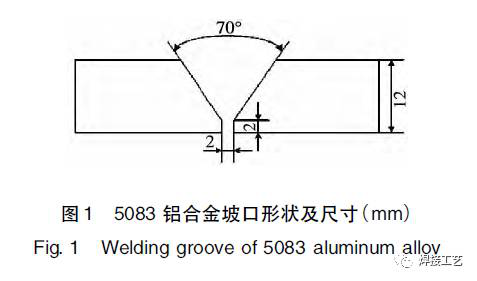

In addition, it could prevent overheating or over-burning of weld tissue. In addition, in order to avoid the tendency of cracking during the welding wire processing. The flux with na-free MgCl2 and KCl as the main components use as the refining agent and covering agent during smelting. Cleaning before welding is an important means to reduce welding defects before this welding test. Because of the use of multi-layer welding and welding workpiece larger. So the use of mechanical cleaning method for cleaning before welding. Using a stainless steel wire brush to polish the pre-prepared groove of the test plate. And the surrounding area to remove the oxide on the surface and brush until the metal luster is exposed.Use acetone to remove grease on the surface of the area to be welded.

http://www.focusweld.com/product-showcase/tig-rod